Tecnología

Invertimos en desarrollos tecnológicos para mantenernos al frente de la industria en la producción del acero y su transformación en alambres y productos de alambre.

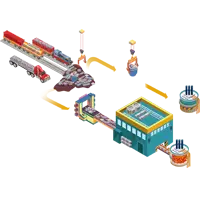

Avances tecnológicos en Acerías

Carga de acero para reciclar caliente

Aprovechamos la energía generada por nuestro proceso de precalentamiento del acero a través de un transportador en el cuál cargamos la materia prima que reciclamos. Este proceso nos permite optimizar el uso de energía y reducir la generación de gases de efecto invernadero, mejorando nuestra capacidad y eficiencia en estos procesos.

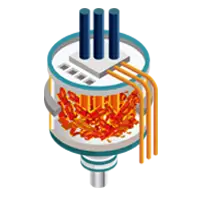

LINDARC

Sistema que optimiza el uso de la energía química, en combinación con la energía eléctrica, para reducer el consumo de energía y tiempos de proceso, disminuyendo así la generación de gases de efecto invernadero.

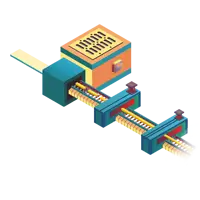

Slitting 5 hilos

Permite al tren de laminación producir varilla de bajo calibre de acuerdo a las necesidades de los clientes, al dividir la palanquilla en varias varillas durante la ultima parte del proceso de laminación. Esta tecnología mejora considerablemente la precisión y seguridad en el laminador, y genera eficiencias en los tiempos y costos de producción.

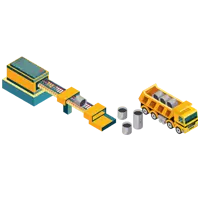

Bobinadora magnética de alta velocidad

Es utilizada al final de la línea de producción de alambrón para enrollarlo a gran velocidad. Utiliza un campo magnético que elimina la vibración, incrementa la velocidad del proceso, mejora su confiabilidad.

Avances tecnológicos en Plantas de Alambre

Líneas de galvanizado de alta velocidad

Recocido: Sustituye el uso de gas por energía eléctrica para calentar el alambre antes del galvanizado, lo que proporciona mayor velocidad de recocido, mayor capacidad de procesamiento y menor consumo de espacio.

Escurrido: Utiliza un proceso de escurrido por inyección de gases, lo cual optimiza el uso de zinc y aumenta la velocidad de secado, al mismo tiempo que permite controlar la capa de zinc requerida según la necesidad del cliente.

Líneas de productos de alambre

Línea de malla hexagonal de alta velocidad: Innovación que pre-dobla y entorcha los alambres de manera continua, lo que permite incrementar la velocidad y eficiencia del proceso.

Líneas de alambre de púas de alta velocidad: incrementa la velocidad y eficiencia del proceso de producción.

Empaque y embobinado: Automatiza el proceso de empaque del producto final, lo que permite incrementar la velocidad y seguridad del proceso.